Over the period April 2022 to August 2022 I was allowed to lead the wonderful project "Formbar 2.0 - An Actuated Information Capture" and work on it together with 3 other dedicated students. In the project which we at the institute,...

... for Human-Computer-Interaction we developed an already existing project further. We focused on the points of optimization of construction and base, modularity, LED lighting and software control compared to the existing project.

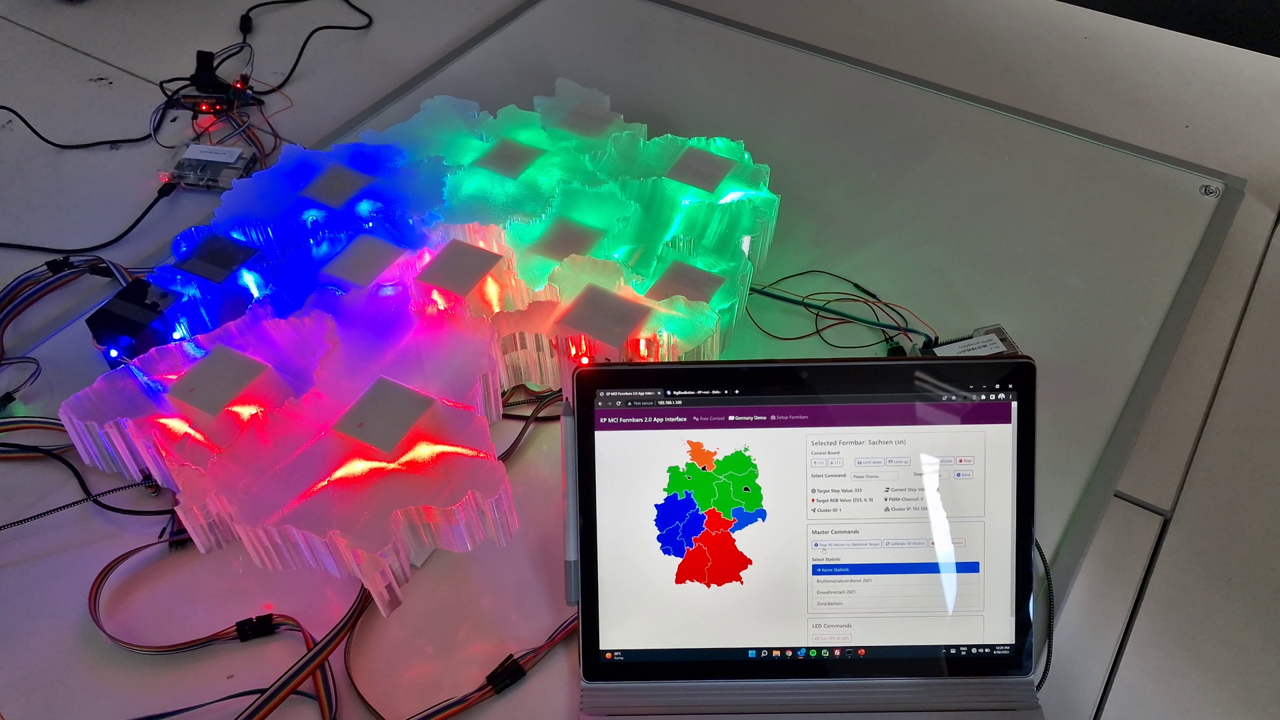

Furthermore, a use case of our formbars was demonstrated via 3D printer and implemented in the form of a map of Germany. Each federal state was assigned a formbar which could raise and lower this state individually and illuminate it as desired.

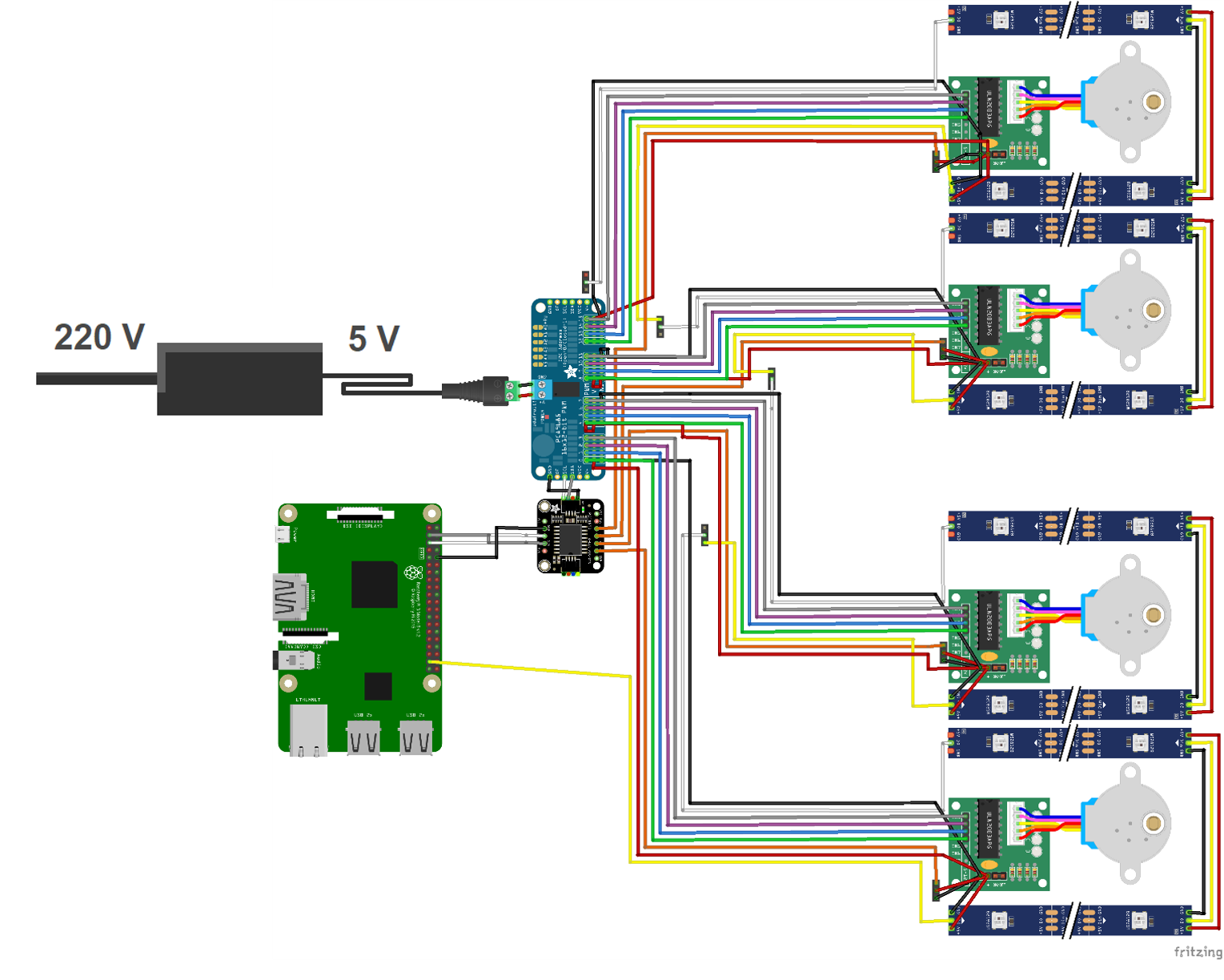

The control of the formbars is done via a Flask API interface which runs on a Raspberry Pi and controls a PWM board via the I2C bus. This PWM board then distributes the commands via a driver board to a stepper motor built into the formbar itself, which in turn moves a guide rail up and down via a gear wheel. A calibration is possible by a button inside the formbar. The 4 LEDs per Formbar are controlled by the Raspberry Pi.

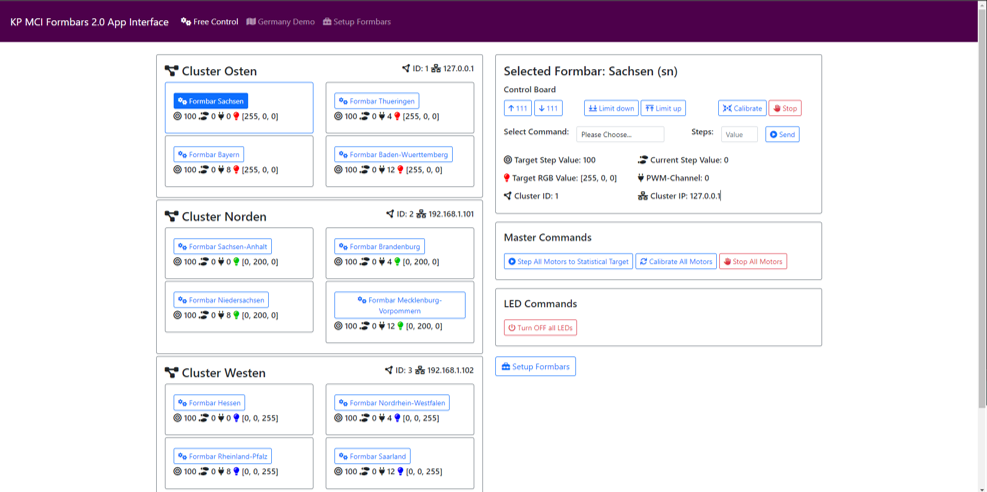

The main part of the project was the development of a simple way to control the whole setup. This possibility is provided by the Flask Api Framework, which uses simple http commands to call functions in the Python backend code.

Since there were more than 1 formbar in our demonstration, namely exactly 13 formbars, and a maximum of 4 formbars could be connected per Raspberry Pi and PWM board, we also used 4 Raspberry Pis. These had to exchange http commands and information with each other to enable control of the entire Germany map.

Furthermore, for the purpose of controllability and usability, the development of a web interface, which allows access to the various http commands, was also the focus of the project.

The web interface can be accessed from any device in the same network as the Raspberry Pis. With this the user can influence the whole configuration of the formbars, commands like drive up, drive down, calibrate and stop. But also other commands like the calibration of the whole setup but also the simultaneous moving of all formbars to the defined target position are possible.

All in all, our project offers a very affordable and yet reliable way to print and build a shape display yourself at home. Through our prototype we have shown the scalability and modularity of information haptification and still leave good possibilities for further development of this project. We see a great applicability especially in museums to provide information especially with maps haptically also to people with visual impairment.